Our Services

Our Services and Capabilities

Assembly Process

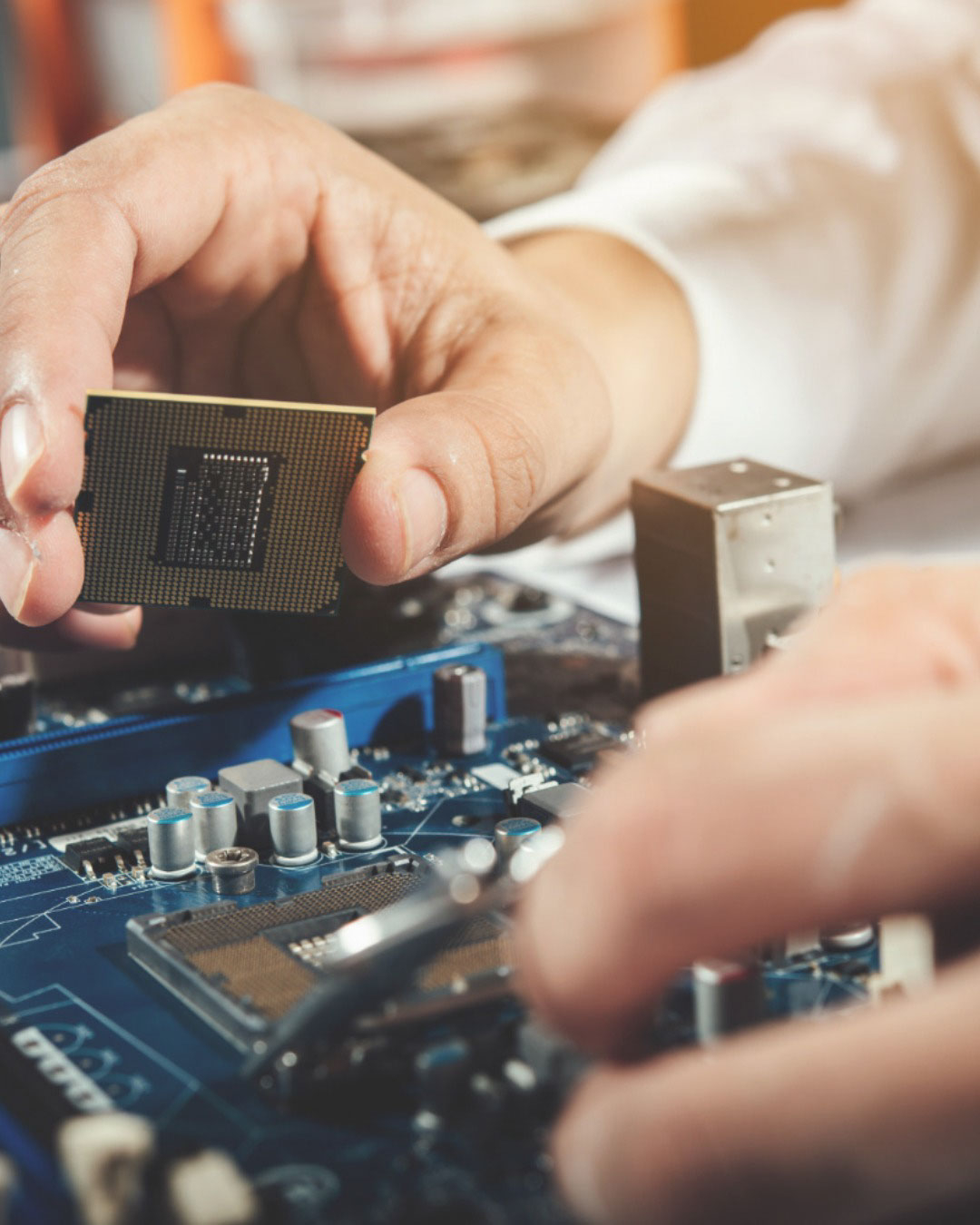

1.We receive your PCB and Components

2.Parts are received and verified during IG

3.Kit Preparation for release to Production

4.SMD Machine Programming

5.Stencil Manufacturing

6.SMD Machine Setup and Component Loading

7.Physical Verification on Machine and Audit

Enhanced Product Quality

Standardization

Compliance

PCB Capabilities

PCB Surface Mount Technology

01005, 0201 and CCGA

COB, MCM and MEM

BGA and uBGA

Flip Chip SOIC

Flip Chip QFPs

Flip Chip TSSOP

Through Hole Assembly

PCB-Service

With our Best in Class SMT Lines we are able to offer PCB Assembly Services for the Most Complex PCB Assemblies for Prototypes, Small Volume and Mass Production

Industrial Control and Automation

Power and Energy

Information and Technology

Automotive

Telecom

Textile

Manufacturing Capabilities

Component range is 01005 to 55 mm

BGA, Micro BGA, QFN, QFP Assembly

Double Sided SMT and BGA Assembly

ESD free environment

SMT NPI / Prototype and High Mix Production

ROHS Compliant Lead Free Soldering using Top Quality Type IV Paste

6CAD Import Software to ensure 100% accuracy and quick changeover

Skilled SMT Operation Team

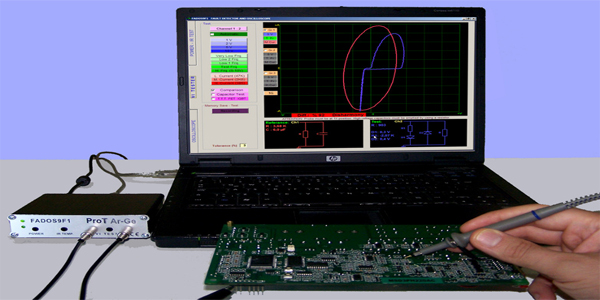

PLC Automation design

A PLC is an industrial computer that serves a basic function: to manage the movements of the automated handling equipment operating in a facility, To do this, the PLC activates and deactivates electrical devices on each machine, such as signal beacons, relays and motors. One characteristic of PLCs is that they operate in real time. That is, they can react and activate the movements of the machinery in a matter of milliseconds. PLC and automation are two concepts that go hand in hand. PLCs have become essential for the industrial and technological development of any company. More and more businesses are turning to logistics automation to boost their warehouse throughput. In a market constantly in flux with same-day deliveries and changing consumer habits, automation delivers speed and reliability in moving large volumes of goods.

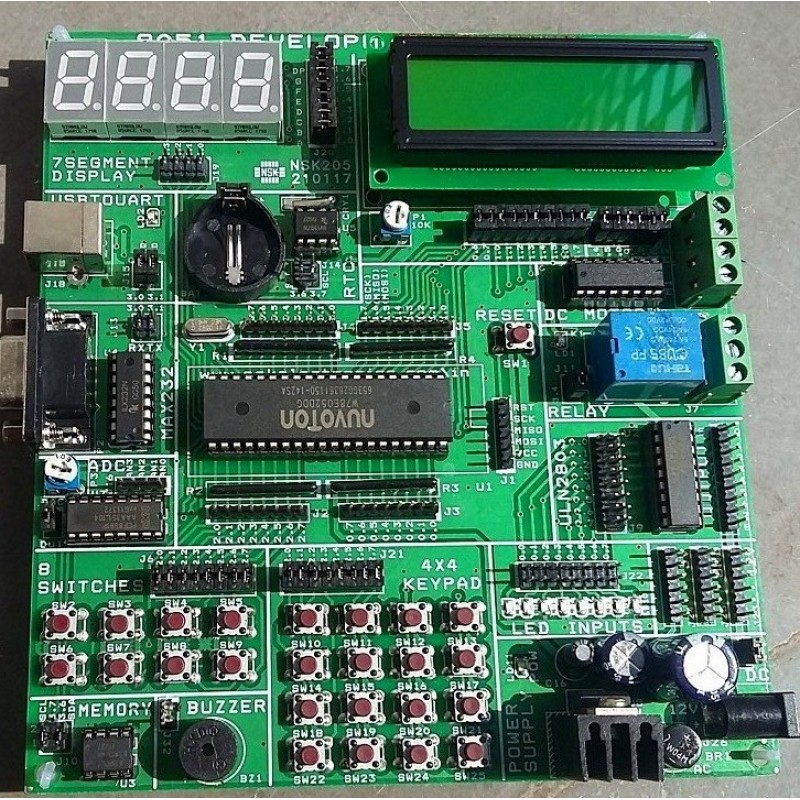

EMBEDDED PRODUCTS DESIGN

Embedded product design is a specialized area that requires trained talent, expensive tools and modern equipment. In addition, there’s also the need for various support services such as industrial design, mechanical design, thermal engineering along with regulatory certifications. For OEMs, it is often difficult to get all these elements under one roof. Furthermore, rapid changes in technology and shrinking time to market, makes the investment in tools, people and infrastructure unattractive. That’s where, services of a reliable partner like Nanotronics would be of immense advantage. Nanotronics offers a wide range of Embedded Design Services that are intended towards transforming an idea into a complete product. This includes devising of System Architecture, Hardware Design, Software Design, Mechanical Design, Prototyping, Validation, Regulatory Certification and Pilot Production.

ELECTRONICS PRODUCT DESIGN

Nanotronics blends technology, creativity and engineering to help customers transform ideas into world-class products and solutions. Nanotronics addresses Internet of things(IoT), Smart home and smart industry sectors. Nanotronics emphasize to build long lasting bricks of electronic product design in this superior world with the goal of providing defective free products. Nanotronics visualize to be one among the ultimate designers of the world in the field of product designing. Nanotronics services comprise of custom Electronics product Design. Nanotronics addresses and bridges the key technology gaps in the Embedded and IoT industry by adopting next-gen embedded technologies in the product development ecosystem. Our in-depth industry knowledge in product engineering, product design, and Electronic manufacturing services can become an edge to provide the complete industrial solution or IoT product design and Production to clients. We provide design services starting from your idea generation through product development to manufacturing.